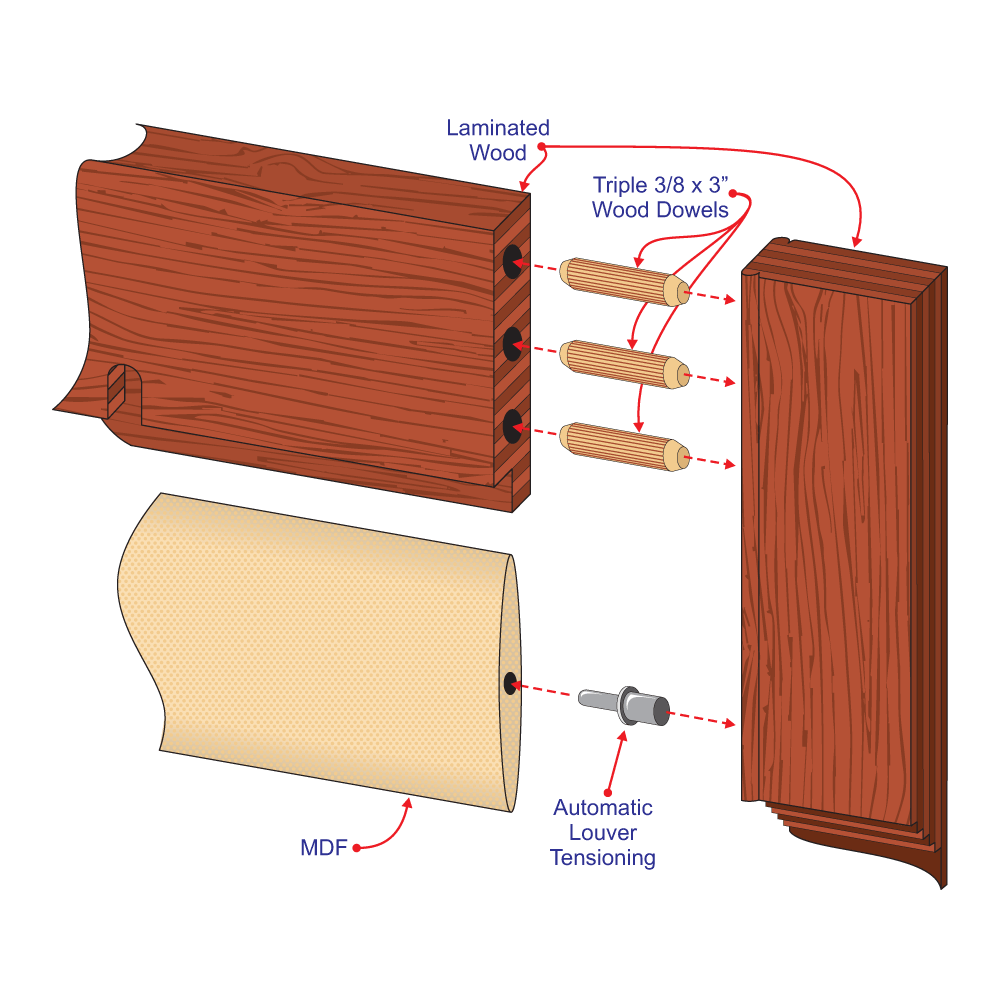

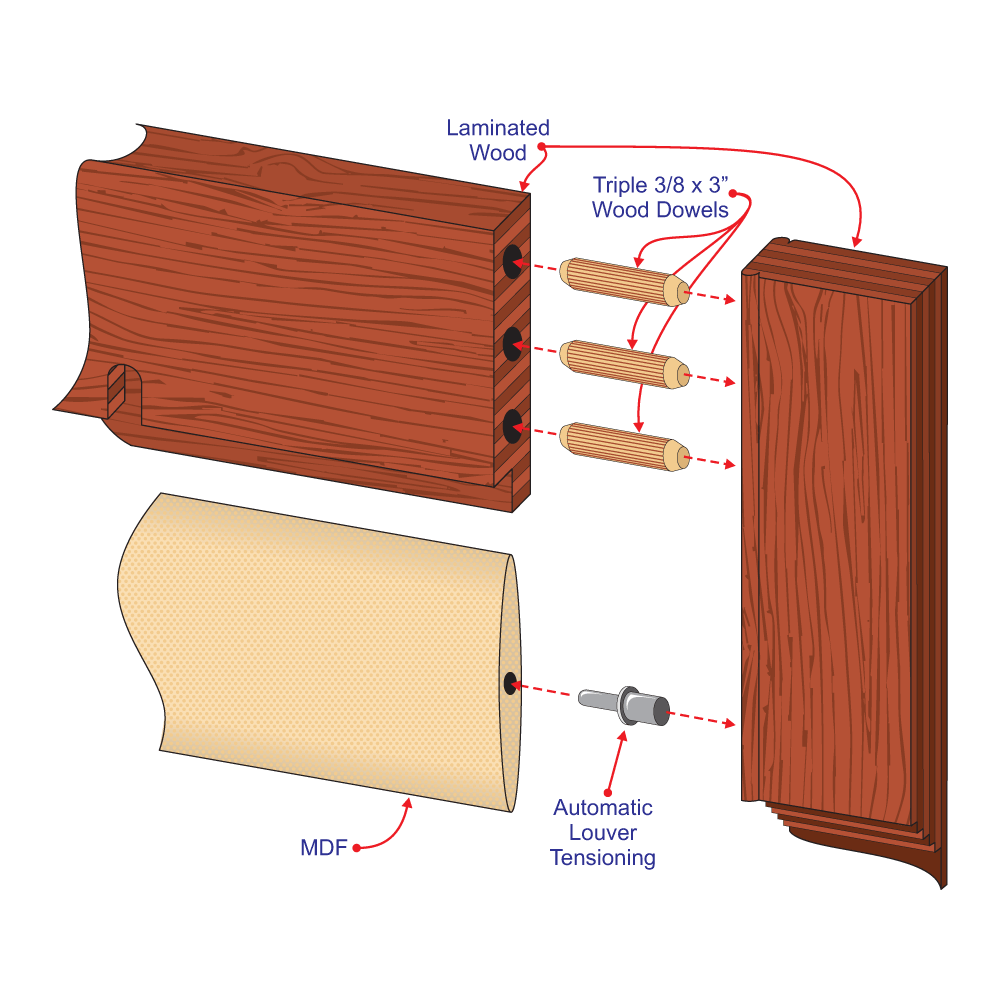

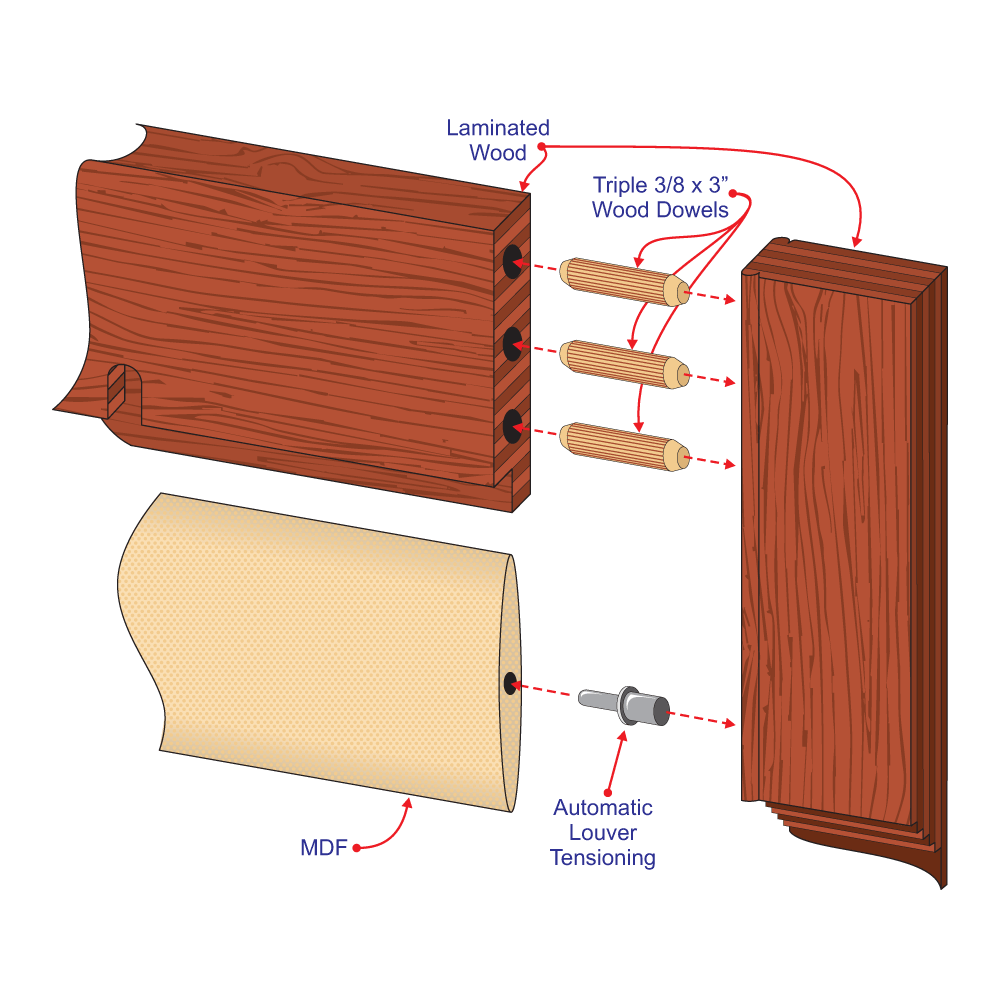

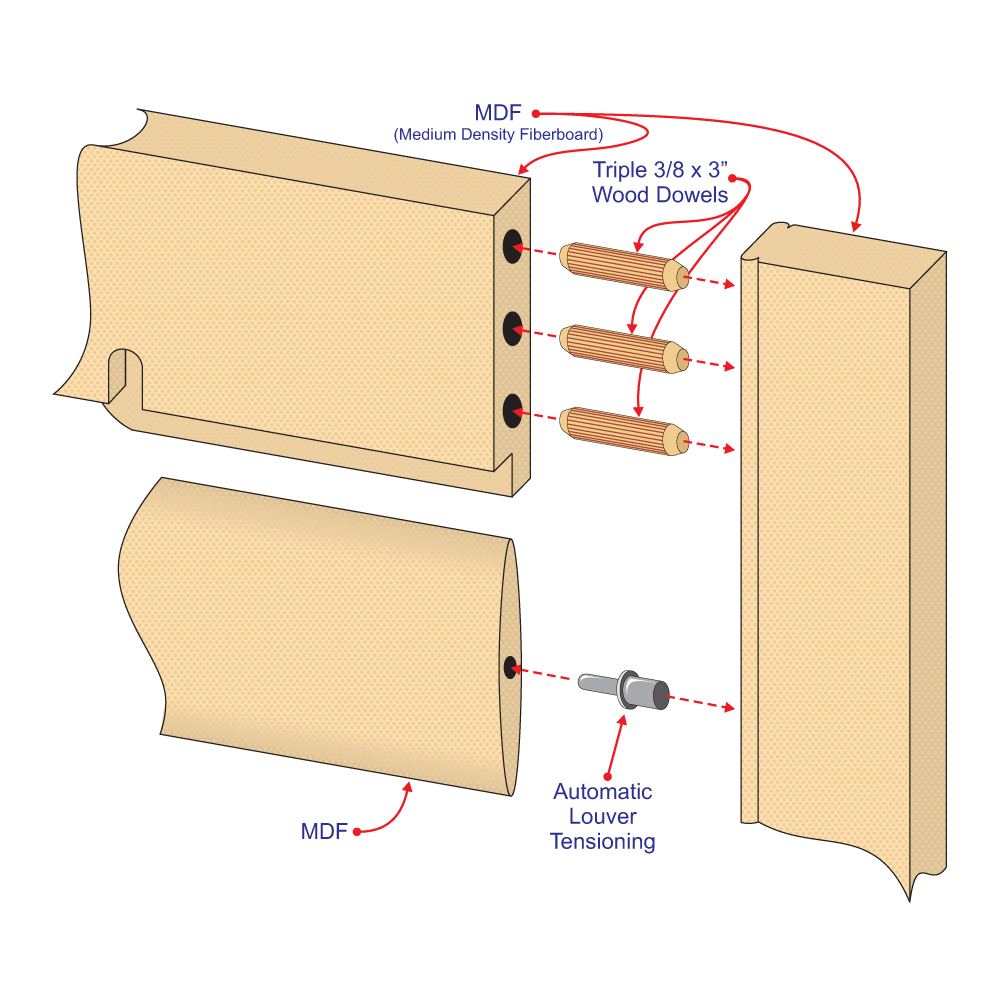

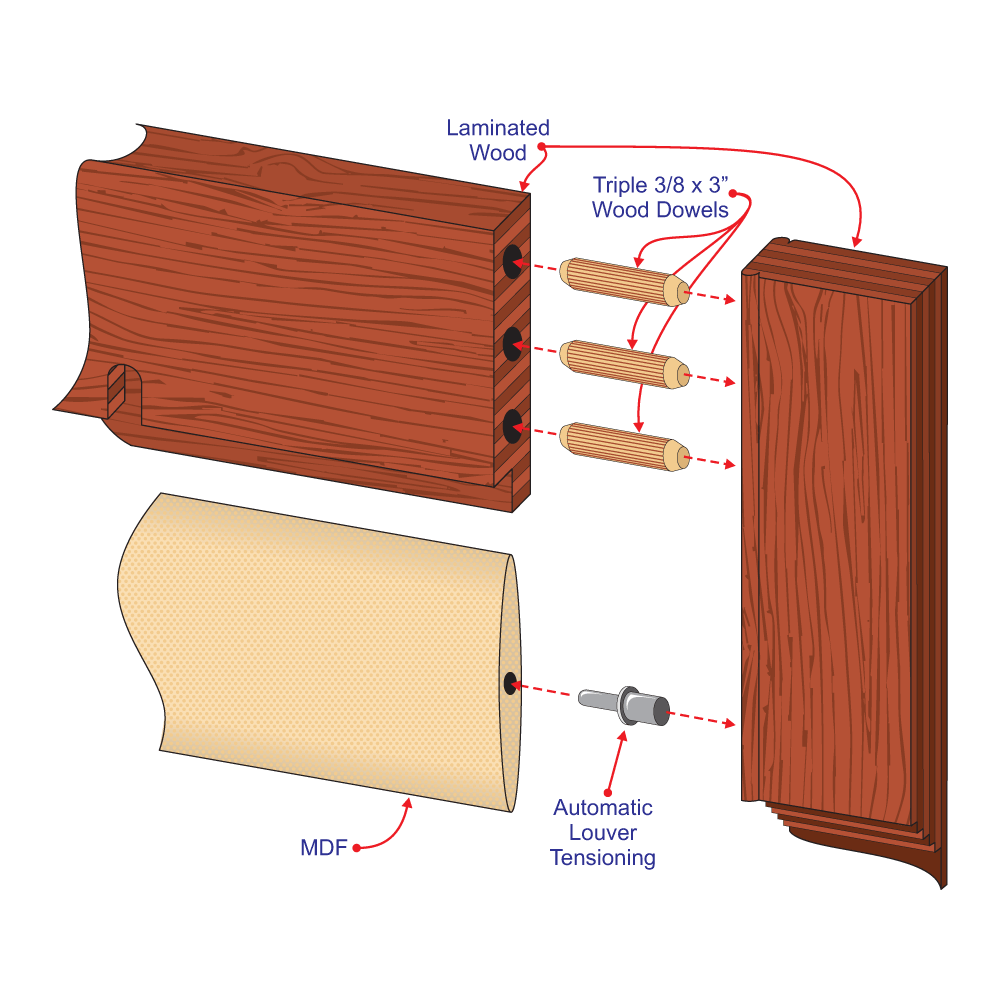

MDF (Medium Density Fiber)

(Medium Density Fiber) shutters are also called “hybrid” and “composite” along with some other trade names. All these window coverings are made from MDF as the base material. MDF is basically sawdust mixed with glue and formed in the shape required. The coatings range from a vinyl wrap to a painted finish. Advantages are cost to manufacture and cost to the consumer. They look very much like more expensive wood shutters. They are stable and resist warping. Disadvantages are their inherent inability to stand up to water, they have the habit of swelling and the finish peeling when exposed to too much moisture. The material is brittle and can easily break under impact. The material will eventually sag under stress over a long period of time. They cannot be successfully stained. This material is rapidly becoming a major part of the window covering market due to its cost and appearance.

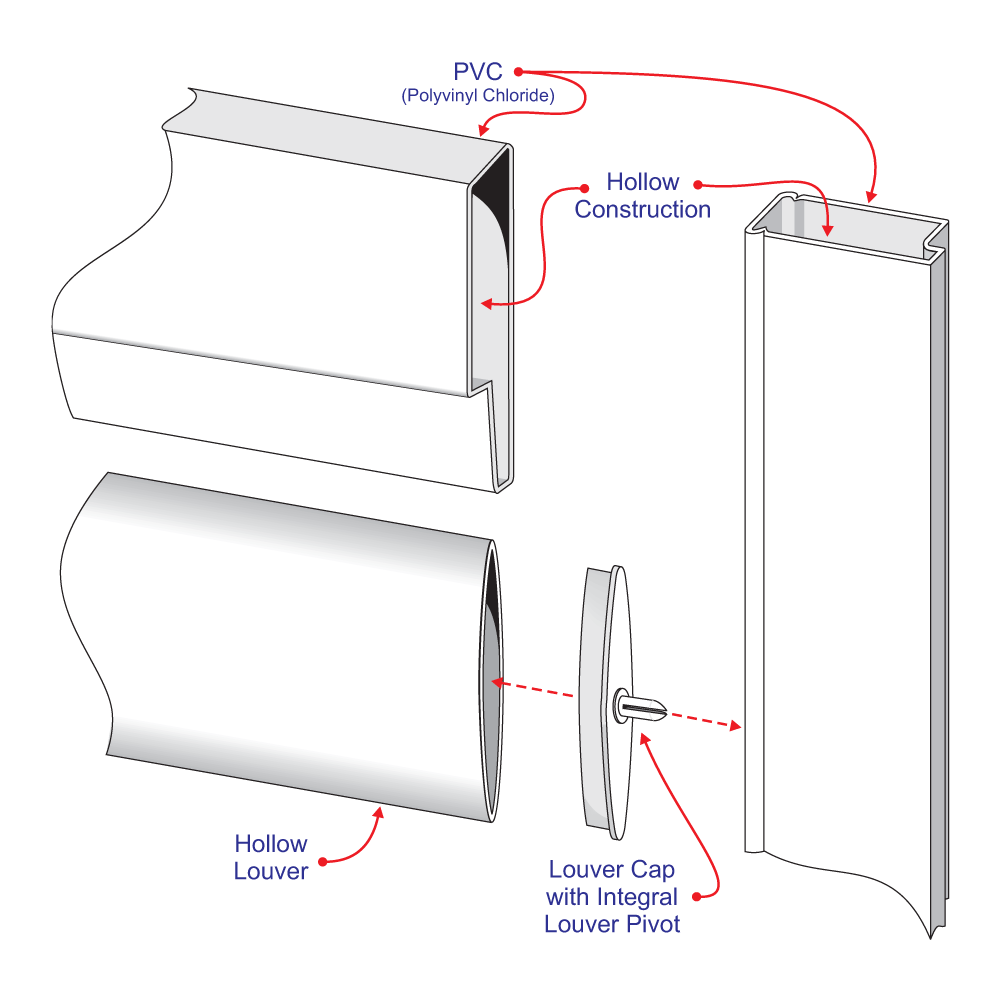

PVC (Poly Vinyl Chloride)

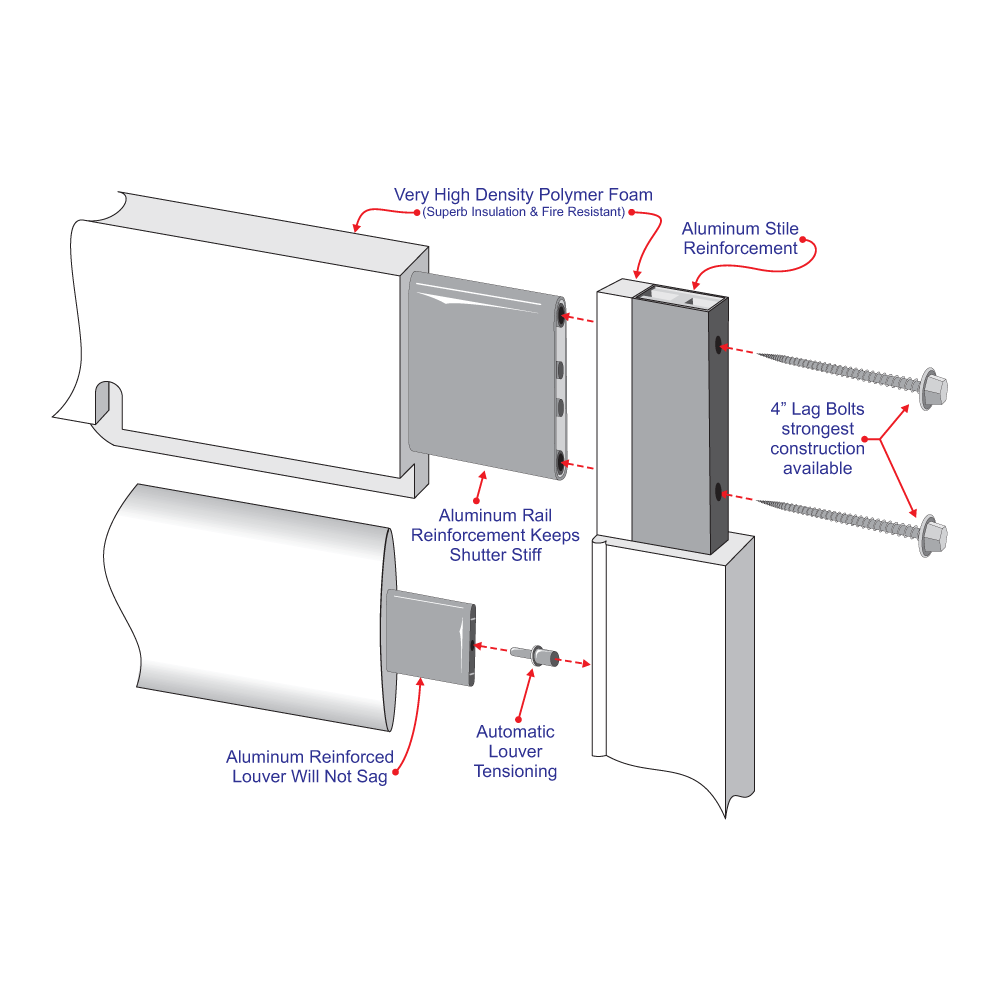

Foamed Synthetics

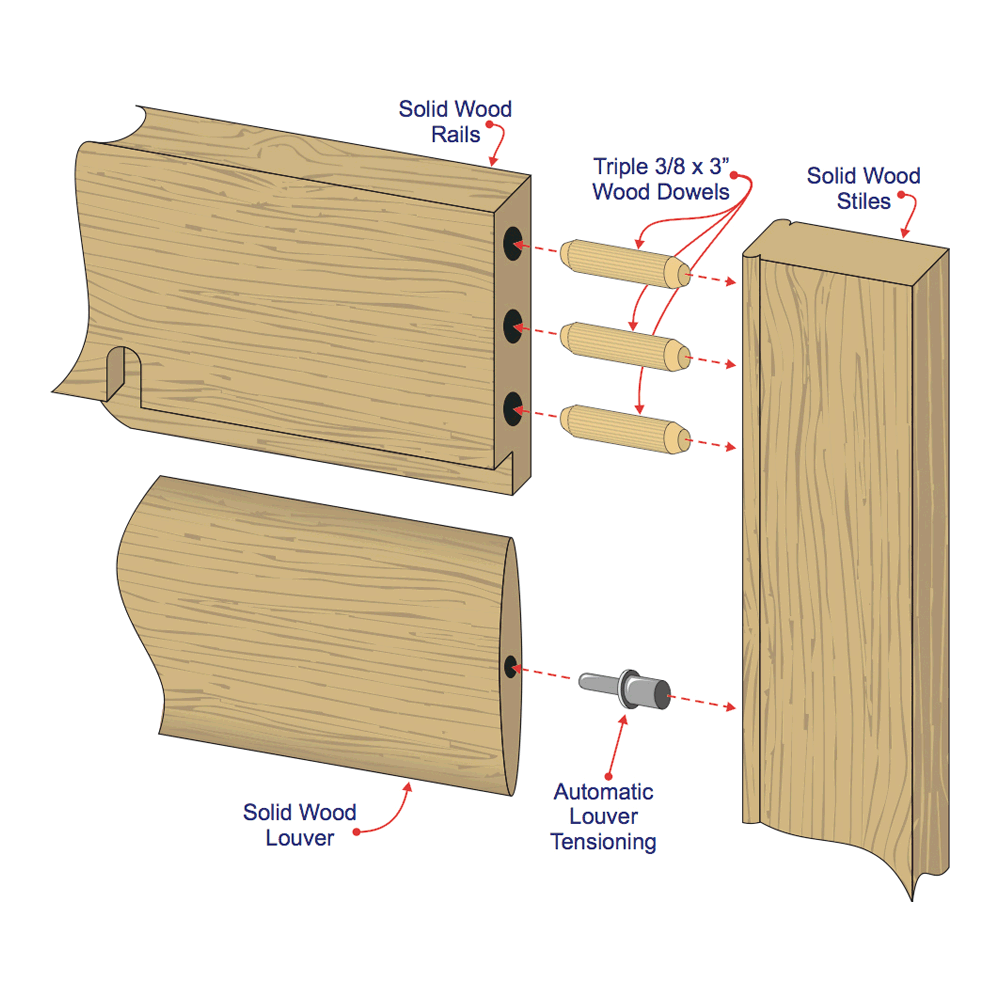

Engineered Wood

Basswood

This is the most common of shutter materials. It has taken over as the material of choice from pine and poplar. Advantages include lightness, stability (the resistance to warping) and flexibility of design. They can be painted or stained, smooth or sandblasted in almost any design required. Disadvantages include being limited to lengths of 12 feet or under and the fact that it requires more preparation than other woods to achieve a quality finish, which adds to the cost. The wood is very homogenous in texture and grain, leading to stains that do not have much figure or beauty to them. Basswood is not water resistant and is not recommended for high moisture situations.

Alder

This may be the “Cadillac” of wood used in the best shutter manufacture. It is a hardwood typically from the Northwestern part of the United States. Advantages include: Hardness of the material, it is greater than most, making it harder to damage accidentally. Almost any design can be accommodated. In appearance it has the grain of cherry wood and is often mistaken for cherry when used to manufacture furniture. It has beautiful grain figuring giving a stain appearance rarely seen in shutter manufacturing. It is stable and takes a painted finish very well. Disadvantages are: limitation of 10 feet to shutter length and cost is higher than most materials do to the high wastage incurred during the manufacturing process. It is not resistant to moisture and not recommended for high moisture situations.

Incense Cedar